Secondary Framing

BLUA Building Solutions designs and manufactures secondary framing systems that provide essential support to roofs and wall sheeting while transferring loads efficiently to the primary framing. These structural members ensure overall stability, strength, and durability of Pre-Engineered Buildings (PEB).

Our secondary framing components include Roof Purlins, Wall Girts, and Eave Struts, each precisely engineered for performance, strength, and easy installation.

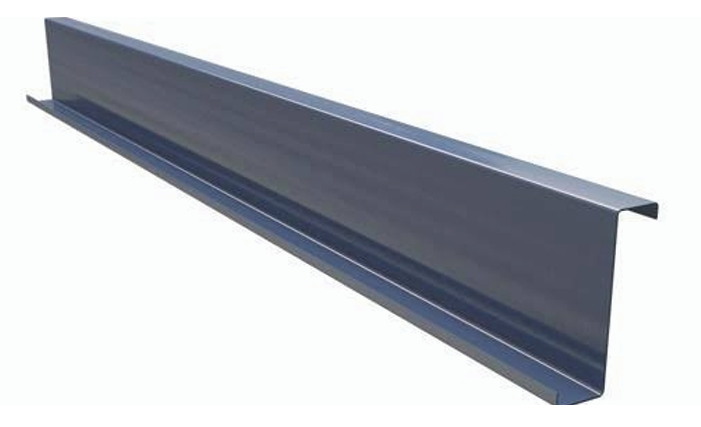

Roof Purlins

Roof purlins are cold-formed Z profiles, typically 200–250 mm deep and made from 1.6 mm to 3 mm thick high-strength steel. They are fixed to the top flange of the rafters using clips bolted to the rafters, ensuring strong connectivity. Purlin ends overlap to function as continuous beams, enhancing load distribution across the roof.

Wall Girts

Wall girts are also cold-formed Z sections, designed for strength and stability. They are attached to the outer flange of the side wall columns using clips bolted to the columns. Like purlins, girt ends overlap to act as continuous beams, providing rigidity and efficient wall support.

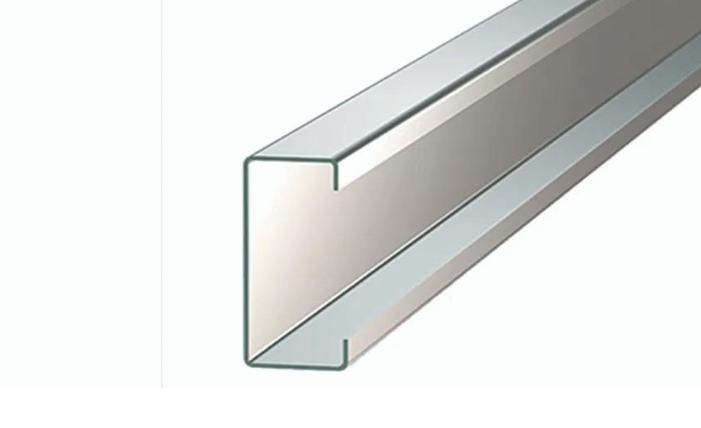

Eave Struts

Eave struts are C-profile members, usually 200–250 mm deep and made from 2 mm to 3 mm thick steel. These are fixed to the outer flange of side wall columns using bolted clips, transferring the roof and wall loads effectively to the main frame while maintaining the building’s edge stability.

Key Features

- High Strength & Precision: Made from high-quality steel for excellent load-bearing performance.

- Efficient Load Transfer: Transfers roof and wall loads safely to the primary framing system.

- Easy Installation: Pre-engineered connections reduce on-site assembly time.

- Corrosion Resistant: Treated materials ensure long-term durability and low maintenance.

- Customizable Profiles: Available in various sizes and thicknesses to match specific project requirements.

Why Choose BLUA’s Secondary Framing?

BLUA’s secondary framing systems are engineered for accuracy, durability, and efficiency. With a focus on quality materials, advanced manufacturing, and fast installation, our framing components ensure your structure remains strong, safe, and sustainable for years to come.